An autonomous fiber-laying robot from DLR

Fibre composite production without boundaries

The task

A vision is taking shape

To create extremely large-scale fibre composite structures, such as wing shells for a modern commercial aircraft, very large gantry systems or articulated robots are needed for laying fibre. For this purpose, the German Aerospace Center (DLR) developed FlappyBot (Fiber Layup Laser Powered Productivity Robot) – an innovative concept for a swarm-capable, autonomous, freely movable, fibre-laying robot that, in future, will make production plants scalable as needed. And that’s where we came in and gave the innovation a face.

The challenges

Solution

How can this technological innovation be rendered through its design?

Process

How can a product that does not yet exist be designed in a user-centred way?

Already in the draft designs zweigrad supplied to us, the great marketing advantage was obvious. zweigrad has developed an excellent design that draws attention without polarising. The FlappyBot’s design actually led to people taking selfies with a robot.

Philipp Sämann, German Aerospace Center

The steps taken

1/ Strategy

User-centred analysis: We analysed the usage environment in today’s production of fibre composite parts and conducted research into technology, trends and analogies.

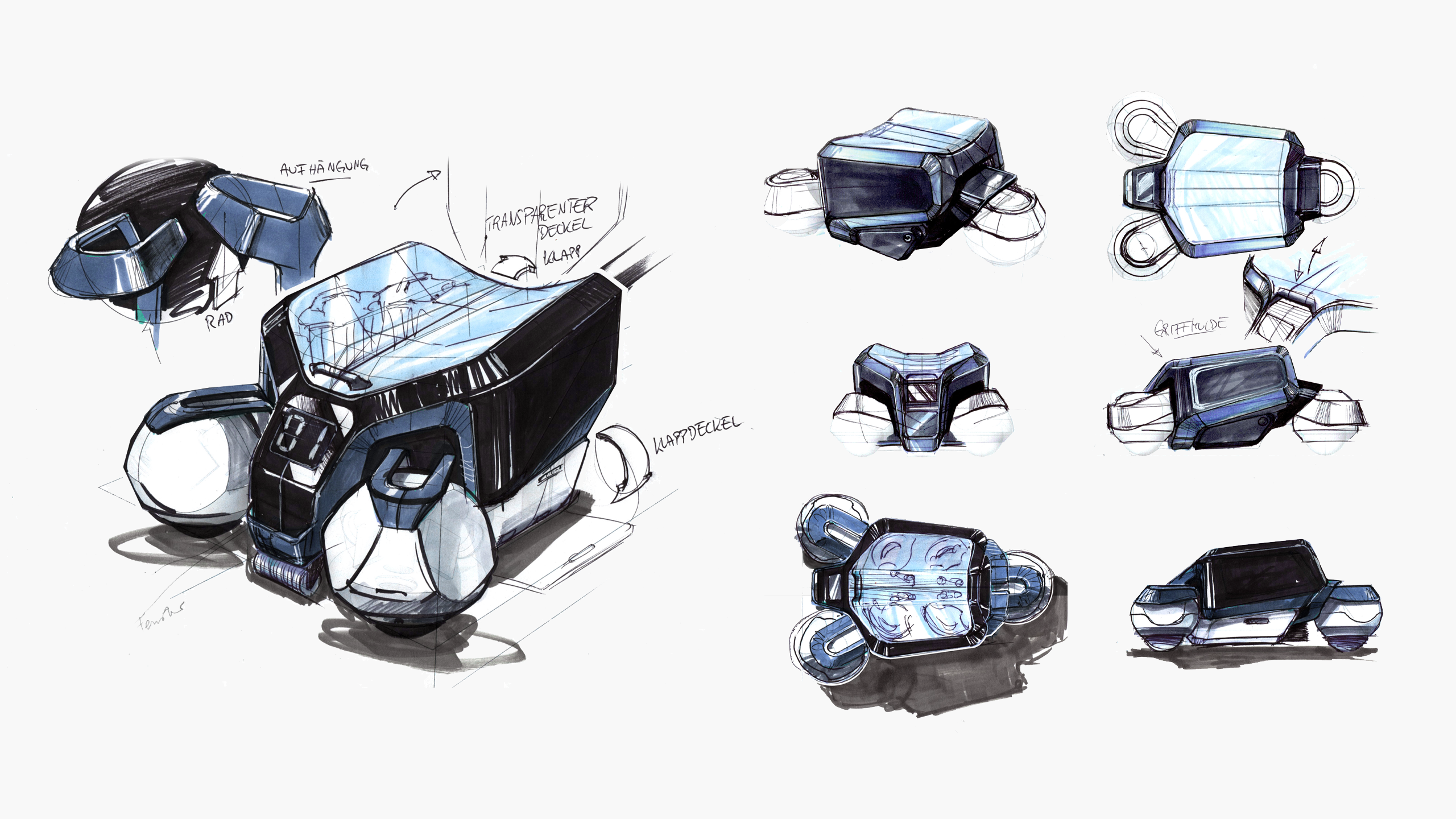

Ideation: All stakeholders involved contributed their ideas and experiences as part of collaborative creative workshops (ideation booster workshops). The aim was to generate as many ideas as possible, irrespective of their assumed viability.

2/ Creation

We channelled the many ideas gathered into coherent design concepts. In our search for an appropriate design language, we sketched and styled, created mock-ups and VR models to assess shapes, proportions and styling of the housing. With the help of click dummies, we tested the user friendliness of the user interface. Along the way, we repeatedly optimised usability and style before completing the final design in 3D CAD.

3/ Realisation

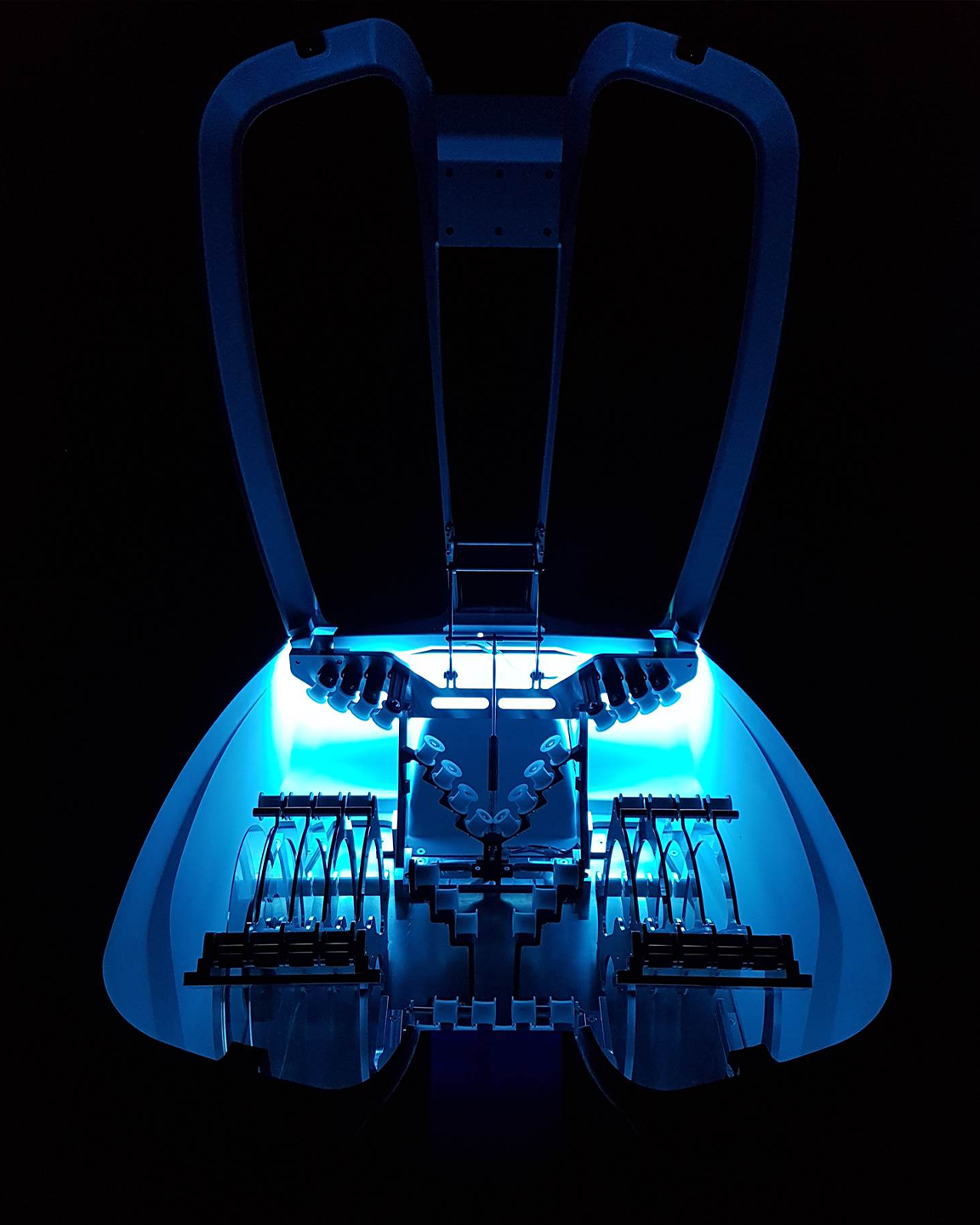

In close collaboration with our team, the 3D CAD data was used to implement the bot in a high-end trade fair model so the global novelty could be presented at the JEC World Show in Paris.

The solutions

High-tech

Using a technical, futuristic and yet emotional design language, we gave a unique face to DLR’s visionary concept. To achieve a holistic product experience, we used all the conceptual freedom we had in arranging the technical components and the operating software. By designing hardware and software as an inseparable unit, future users of FlappyBot are guided with utmost clarity.

With a personal touch

Almost insect-like, the innovative high-tech device incorporates a variety of new technologies through an emotionally appealing design. The housing with its compact shape, the high-contrast colour scheme and the dynamic lines make FlappyBot DLR’s innovation ambassador.

Presentation at the JEC World in Paris 2019

Milestones

Ideation Workshop

Cooperative creative workshop with all stakeholders for a holistic design

Creation (ID & UX)

Bot conception in different design directions, transfer of use cases into software using wireframes

CAD & UI Design

Definition of the hardware design in 3D-CAD and design layout of the digital HMI

High end exhibition model

1:1 functional high-end exhibition model, presented at the JEC World in Paris